SMCC Induction Heating Unit

Induction heating unit for adhesive precuring, medium-frequency converter with self-contained cooling water supply

-

Compact Modular Design

- Separate generator and cooling system

- Maximizes system layout flexibility Improves maintainability

-

Water / air cooling-unit

- Optional water / water cooling unit integrated in the cabinet

- Individual cooling circuit control with current flow quantities

- Plug systems for power outlets and cooling water supply

- Meets current techniques and standards for generators including electromagnetic compatibility (EMC)

-

Temperature registration of up to 8 measuring points

- Column and curve diagram for component temperature on the display

- INTERBUS or PROFIBUS control

- Ethernet connection for process data

SMCC Specifications

Power Range : 40 kW

Operation Frequency : 5 – 20 kHz

Standard Dimensions : 1600 X 600 X 700 mm

(On Transport Wheels)

Transformer Unit : External (on the Curing Station)

Dimensions : 450 X 350 X 300 mm

Flexible Connection : Max. 12 m Separation

Power Switch : Up to 3 Curing Stations

Process Control : Cycle Time and Temperature Profile

Interconnection Control : INTERBUS, PROFIBUS

Interconnection Data : ETHERNET

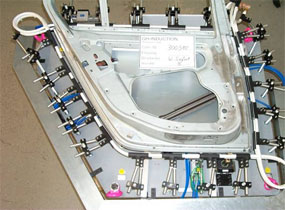

The HABIFLEX System (patented)

Patent for flexible inductor system for applications in the heating of bonded hems

Patent no. 198 07 099-3

Especially suitable for inductor systems with complex contours

- Flexible Heating Conduction and Holders

- Simplifies maintenance

- Less Distortion

- Constant Temperature Distribution

- Complete Hem Cure or Partial

- No Junction Points For the Components

- Periphery

- Electric Shock Protection

- Each Turn Can Be Adjusted Universally

- Reduces Heating-up Period Compared to a One Turn Inductor By Up To 80%

- Better Quality Due To a Constant Temperature Profile Between External and Internal Metal.

- A Mechanical Assembly Technique Allowing the Direct Mounting of the Inductor System On Site

- Flexible – Allowing Adjustment / Fine Tuning to the Contour of Each Component and for Future Product Changes.

GH DATA-LOGGER

Copyright 2018 Global System Engineering Group